BuySellBA

Administrator

It is in use in more than 10,000 houses under construction and is the construction system chosen by the new generations in Argentina - Infobae

Source:

Está en uso en más de 10.000 casas en obra y es el sistema de construcción que eligen las nuevas generaciones en la Argentina

Surgió como formato en seco para complementar estructuras existentes. Gana popularidad entre quienes optan por vivir en áreas apartadas de las grandes ciudades o que buscan ampliar sus hogares. El costo oscila entre USD 700 y USD 900 por metro cuadrado

March 31, 2024

It emerged as a dry format to complement existing structures. It is gaining popularity among those who choose to live in areas away from large cities or who are looking to expand their homes. The cost ranges between USD 700 and USD 900 per square meter

By José Luis Cieri

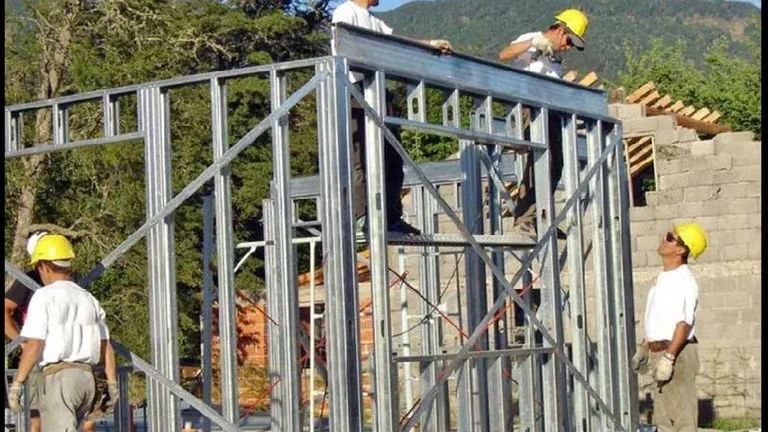

A 200 m2 steel frame house can be built in 6 months

The steel frame construction system , basically steel structures, continues to advance in Argentina. Today there are more than 10,000 homes under development under this modality, according to estimates by the Argentine Chamber of Steel (CAA).

This building method, which was initially used as a complement to other structures, gained ground in the residential field thanks to its benefits in terms of efficiency, sustainability and speed of execution.

It uses galvanized steel profiles to create a robust skeleton capable of supporting both large-scale buildings and family homes. From the sector they reported that this technology not only offers superior resistance compared to concrete, but also allows considerable savings in resources during the construction process.

This system is characterized by the use of metal beams and walls composed of external cement plates and internal plaster, with glass or mineral wool insulators between them.

Pandemic boost

The increase in preference for steel framing was notable, especially during the pandemic period, when dozens of families bought lots and chose to move to larger spaces outside of large cities, valuing the speed of construction offered by this modality.

This method is characterized by the use of metal beams and walls composed of external cement plates and internal plaster.

Santiago Lesser , commercial director of Ternium, told Infobae that this trend responds to the demand for housing by young people under 35 years of age, who are looking for quick and economical housing solutions. This growing demand is reflected in the geographical diversification of the system, with works underway not only in the city of Buenos Aires, province of Buenos Aires and Santa Fe, but also in Mendoza, Córdoba, and Rosario, among other parts of the country.

The adoption of the steel frame in Argentina received a notable boost from 2018, when it was officially recognized as a system equivalent to concrete construction.

Furthermore, steel framing stands out for its energy efficiency, as it improves the thermal performance of buildings, reducing the need for cooling and heating. This aspect, together with the 100% recyclable nature of steel, positions the system as a low carbon footprint option in the sector, highlighting the combination of resistance, sustainability and efficiency.

How dry construction was born

Although many assume that dry construction is a new technique, the reality is that it has been used for more than 200 years. As time went by, it was improved and adapted to new needs and technologies.The system began to become popular when sawmills were automated and nail production was industrialized, causing a sharp drop in manufacturing costs. The same thing happened with construction times, which were reduced.

Housing made of steel frame

What is most innovative is the implementation of this system in the world of housing. After World War II, many countries had a high demand for residential work and needed to build houses quickly. Within this framework, between 1948 and 1950, a company called Lustron (in the United States) built 2,500 prefabricated homes with galvanized steel structures.

“The system allows saving resources in all stages of construction” (Pablo Marandino, Pradecon)

At the end of the eighties and beginning of the nineties it was already implemented in the sector as it constituted a more efficient, ultra-light, sustainable and predictable method.

“In addition to resistance and quality, the system allows for resource savings in all stages of construction,” explained Pablo Marandino , commercial coordinator of Pradecon, steel industry and distributor.

In the case of houses, they are built with galvanized steel metal beams, the walls have cement plates on the outside and plasterboard on the inside. Glass or mineral wool is placed between them as insulation.

Preferences

From the CAA they explained that the system achieves execution times 40% lower than traditional construction.The speed in the execution of the construction system was a determining factor for the growth of steel framing . It allows the construction of a turnkey house of 200 m2 in a period of 4 to 6 months, with a team of approximately 12 people throughout the installation process.

Lesser expanded: “This captured what the sector calls the young house , homes for an age range of less than 35 years who are interested in having their own home quickly and without fluctuations in costs. “There is a consolidation in the single-family housing segment, covering a multiplicity of sizes, and throughout the country.”

Specifically, steel framing has been in Argentina for more than 30 years, however the growth was very marked during the pandemic.

This type of housing is considered evolutionary, since it allows you to start with a design that includes a living room, kitchen, bathroom and a bedroom initially, and later add other bedrooms, a laundry room and other rooms according to needs. It stands out for its flexible model that adapts to the owner's changes and requirements over time.

Prices

The house models stand out for their modern and attractive design. Prices per square meter vary between USD 700 and USD 900, although if you wish to include luxury details and imported materials, the cost can rise to USD 1,200 per m2.The variety of prices in the steel framing market is considerable, influenced by factors such as steel cuts and customer preferences. “However, in general, it is observed that prices are slightly above inflation,” they reported from the camera.

Steel frame homes are advancing throughout the country. Inside in Córdoba, Rosario, Mendoza, among other places

Coatings

The finishes of these homes offer a wide variety of options, even including alternatives to wet systems.In the case of interior coverings, it is common to use plasterboard, which comes in different types. These plates can be coated with various materials.

As for the floors, once a uniform substrate was achieved, which can be achieved by means of a cementitious support plate, you can practically choose from wooden floors to carpets, ceramic or porcelain tiles, the options are varied.

Interior and exterior finishes can be made according to the client's needs

On the other hand, when it comes to exterior walls, steel framing systems usually have standardized finishes. However, as with interior plastering, it is possible to achieve finishes that imitate traditional plaster, thus providing flexibility in design and a corresponding aesthetic.

www.buysellba.com